The oil palm self-cleaning street light project is an innovative infrastructure initiative that integrates solar-powered lighting with automated maintenance technology to serve agricultural sectors. It utilizes oil palm biomass waste for structural components while employing self-cleaning mechanisms to prevent tropical dust and organic debris from reducing solar panel efficiency in remote plantations.

The Intersection of Agriculture and Illumination

In the sprawling oil palm plantations of Southeast Asia and Africa, lighting is more than a convenience—it is a critical safety requirement. However, the very environment that produces the world’s most versatile vegetable oil is also one of the most hostile for traditional infrastructure.

Tropical humidity, persistent organic dust, and the sheer remoteness of these estates make grid-based lighting nearly impossible. This is where the oil palm self-cleaning street light project steps in. By bridging the gap between agricultural waste management and renewable energy, this project offers a blueprint for a circular economy that lights the way for rural development.

Why Self-Cleaning Technology is Non-Negotiable

In a typical urban setting, a solar panel might lose $5\%-10\%$ efficiency over several months due to dust. In an oil palm plantation, that figure can skyrocket to 30% in less than three weeks.

The “soiling effect” in these regions isn’t just mineral dust; it’s a “bio-crust” composed of pollen, sap, and decomposing organic matter that acts like an adhesive. Standard solar street lights fail here because the cost of manual cleaning in remote areas often exceeds the value of the energy generated.

The Three Pillars of Self-Cleaning Mechanisms

-

Hydrophobic Nano-Coatings: Modern projects use a chemical layer that mimics the “Lotus Effect.” Water beads up and rolls off, taking dust particles with it.

-

Electrostatic Repulsion: Some advanced units employ a transparent electro-dynamic screen (EDS). By applying a small electric charge, the panel physically repels dust before it can settle.

-

Mechanical Robotic Wipers: For heavy-duty environments, integrated brushes operate on a timer (usually at dawn and dusk) to physically clear the surface, powered by a dedicated secondary battery to ensure the main light remains unaffected.

Read Also: Self Cleaning Street Light Palm Oil: Smart Plantation Lighting

From Waste to Wattage: The Oil Palm Connection

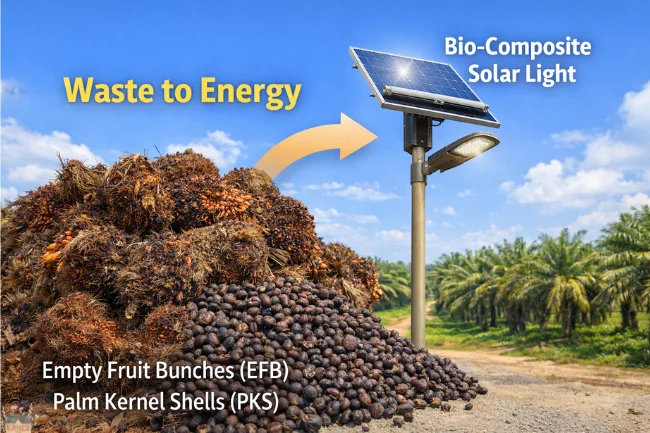

What truly separates the oil palm self-cleaning street light project from generic solar initiatives is its use of the “circular bio-economy.” Research is currently focused on repurposing the massive volume of biomass generated by the industry—such as Empty Fruit Bunches (EFB) and Palm Kernel Shells (PKS)—to build the lights themselves.

Bio-Composite Housings

Traditional street light housings are made of aluminum or high-density plastics. These are expensive to transport to remote areas and have a high carbon footprint.

-

Innovation: Researchers are now developing bio-composites using oil palm fibers as reinforcement for polymer resins.

-

Result: These housings are lightweight, corrosion-resistant in high humidity, and utilize the thousands of tons of waste already sitting on the plantation floor.

Activated Carbon Batteries

The shells of the oil palm fruit are rich in carbon. Through a process called pyrolysis, this waste can be converted into activated carbon, which is a key component in supercapacitors and lithium-sulfur batteries. While still in the pilot phase, these “green batteries” could eventually replace traditional lead-acid cells, making the entire project 100% sourced from the plantation it illuminates.

Technical Comparison: Standard vs. Self-Cleaning Smart Lights

The Economic Impact: A 5-Year Outlook

Critics often point to the higher initial investment of the oil palm self-cleaning street light project. However, a cost-benefit analysis reveals that the “Smart” approach is actually the more frugal choice for large-scale agricultural operations.

Reduced Operational Expenditure (OpEx)

Manual cleaning for a plantation with 500 street lights requires a dedicated team, a vehicle, and thousands of gallons of water. By automating this process, the plantation saves approximately $12,000–$15,000 annually in labor and fuel costs alone.

Extended Hardware Longevity

Batteries are the most expensive component of any solar project. When a panel is covered in dust, the battery undergoes “deep discharge” cycles because it never reaches a full charge during the day. This kills the battery in 12–18 months. Because the self-cleaning system ensures a full charge every day, the battery life is often doubled, delaying expensive replacement costs by years.

Overcoming Environmental Challenges

The tropical belt presents unique hurdles that standard solar projects aren’t designed to handle. The oil palm self-cleaning street light project integrates specific engineering solutions for these “tropical traps”:

-

Humidity Management: IP66 and IP67-rated enclosures prevent internal condensation, which is the primary cause of LED flicker and circuit failure in the tropics.

-

Heat Dissipation: Bio-composite housings are designed with aerodynamic vents to manage the $30^{\circ}C$ to $45^{\circ}C$ ambient temperatures, ensuring the LiFePO4 (Lithium Iron Phosphate) batteries don’t overheat.

-

Pest Resistance: The use of specific resins in the oil palm fiber composites makes the poles and housings unappealing to termites and other boring insects common in agricultural zones.

Read Also: Solar Panels Serial or Parallel: Complete Wiring Guide

The Role of IoT and Smart Monitoring

Modern projects are no longer “standalone” units. They are part of an Internet of Things (IoT) network. Using LoRaWAN (Long Range Wide Area Network) technology, a single manager can monitor the health of thousands of lights from a central dashboard.

If a wiper mechanism jams or a battery capacity drops below a certain threshold, the system sends an automated alert. This “proactive maintenance” ensures that no area of the plantation is ever left in the dark, significantly reducing the risk of theft and improving worker safety during early morning harvests.

Frequently Asked Questions (FAQs)

1. Does the cleaning mechanism use water?

Most units in the oil palm self-cleaning street light project are “dry-clean” systems. They use a combination of vibration and mechanical brushes. This is essential for remote areas where water hauling is expensive. However, some “hybrid” models can utilize tropical rainfall to enhance the cleaning cycle.

2. Is the bio-composite housing durable enough?

Yes. When oil palm fibers are treated and bonded with UV-resistant resins, the material has a strength-to-weight ratio comparable to metals. It is specifically designed to resist the high UV index and acidic rainfall common in equatorial regions.

3. What happens during the monsoon season?

These systems are equipped with high-density LiFePO4 batteries that typically offer 3 to 5 days of autonomy. This means the light will continue to function even after several consecutive days of heavy cloud cover or rain.

4. How often does the cleaning cycle run?

In most plantation settings, the cleaning cycle is programmed to run twice a day: once at dawn to clear any dew and overnight debris, and once at dusk to ensure the panel is clear for the first light of the next day.

5. Can this technology be used in other sectors?

Absolutely. While optimized for the oil palm industry’s waste and dust profile, the technology is being adapted for rubber plantations, cocoa estates, and even large-scale desert solar farms.

6. What is the project theory of automatic street lights?

The theory relies on Light Dependent Resistors (LDRs) or astronomical timers that detect ambient light levels, automatically completing a circuit to trigger illumination at dusk and breaking it at dawn to conserve energy.

7. How to explain a street light project?

A street light project is an integrated infrastructure plan designed to provide consistent nighttime visibility and public safety by deploying high-efficiency LED luminaires powered by either the electrical grid or localized solar energy systems.

8. How to reduce light pollution with design?

Light pollution is mitigated through “Full Cut-off” fixtures that direct light strictly downward, the use of warm-toned LEDs (under 3000K), and motion sensors that dim lights when no activity is detected.

9. What is the cost of a solar street lighting system?

A professional-grade solar unit typically ranges from $800 to $2,500 per pole, depending on features. However, it eliminates monthly utility bills and the high cost of trenching electrical wires.

Conclusion: Lighting the Path to Sustainability

The oil palm self-cleaning street light project is a testament to the power of localized innovation. By recognizing that a “one-size-fits-all” urban solar light cannot survive the rigors of an agricultural estate, researchers have created a solution that is as resilient as the industry it supports.

As the world shifts toward more transparent and sustainable supply chains, integrating green infrastructure into the heart of oil palm production isn’t just a safety measure—it’s a statement of environmental responsibility.

Learn about Oil Palm Lamp Project Street Lamp Oil Palm

For broader information, visit Wellbeing Makeover

I’m Salman Khayam, the founder and editor of this blog, with 10 years of professional experience in Architecture, Interior Design, Home Improvement, and Real Estate. I provide expert advice and practical tips on a wide range of topics, including Solar Panel installation, Garage Solutions, Moving tips, as well as Cleaning and Pest Control, helping you create functional, stylish, and sustainable spaces that enhance your daily life.