The transition to renewable energy often focuses on the efficiency of the cells or the capacity of the inverter. However, the structural integrity of a solar installation relies entirely on the mounting system. Choosing the right solar brackets for 365W solar panels is a critical step in ensuring that an investment remains secure, productive, and compliant with local building codes for decades.

A 365W panel is a common choice for both residential and commercial projects due to its balance of size and power output. Because these panels carry specific physical dimensions and weight profiles, the hardware used to fix them to a roof or ground mount must be engineered to handle both the static load of the glass and the dynamic loads of wind and snow.

Understanding the Role of Mounting Hardware

Solar brackets are more than just simple metal clips; they are the interface between a high-tech energy generator and a building’s structure. Their primary purpose is to maintain the optimal tilt angle for energy production while protecting the roof’s waterproofing.

When dealing with a 365W module, which typically measures approximately 1.7 to 1.8 meters in length and about 1 meter in width, the “sail area” is significant. In high winds, a solar array can act like a wing, creating massive uplift forces. Properly rated solar brackets for 365W solar panels distribute these forces into the rafters or the mounting substrate, preventing mechanical failure or damage to the panel’s internal silicon wafers.

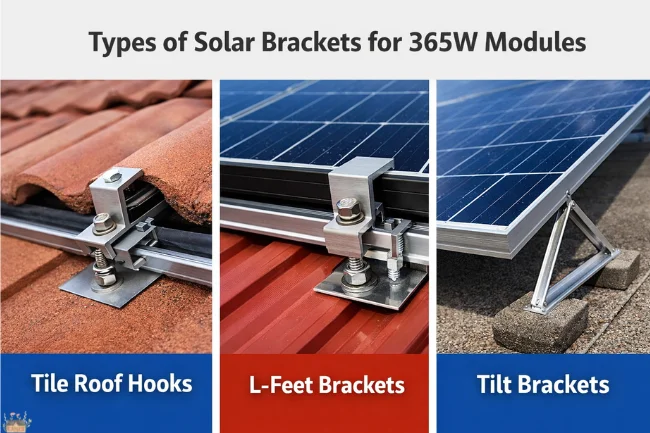

Types of Solar Brackets for 365W Modules

The choice of bracket depends largely on the installation surface. Different roofs require different attachment methods to ensure long-term stability and leak prevention.

Pitched Roof Attachments

For standard residential installations, pitched roof mounts are the most common. These systems usually involve a combination of flashing, L-feet, and rails.

-

Tile Roof Hooks: These are shaped to snake around or under clay or concrete tiles, attaching directly to the wooden rafters without requiring the installer to drill through the tile itself.

-

L-Feet: Commonly used on metal or composite shingle roofs, these brackets provide an adjustable height to ensure the rails are level, even if the roof surface is slightly uneven.

-

Standoffs: These raise the panels higher off the roof surface, which is particularly beneficial in hotter climates as it allows for better airflow and cooling of the 365W modules.

Flat Roof Tilt Kits

Flat roofs present a different challenge. Since there is no natural incline, the brackets must provide the necessary angle (usually between 10 and 30 degrees) to maximize sunlight absorption. These often come as triangular “A-frame” brackets. They can be mechanically fastened to the roof or held in place by heavy concrete blocks, known as a ballasted system, to avoid roof penetrations.

Ground Mount Structures

When roof space is limited, ground-mounted racks are an excellent alternative. These brackets are often more robust, as they are exposed to the full force of the weather without any shielding from a building. They typically utilize galvanized steel or high-grade aluminum legs driven into the ground or set in concrete piers.

Material Matters: Aluminum vs. Stainless Steel

The environment in which the panels are installed dictates the material requirements for the brackets. 365W panels are designed to last 25 years or more, and the mounting hardware must match this lifespan.

Most modern solar brackets are made from Anodized Aluminum (6005-T5). This material is preferred because it is lightweight, which reduces the total load on the roof, and it possesses a natural oxide layer that prevents deep-seated corrosion.

For the fasteners—the bolts, nuts, and washers—Stainless Steel (SUS304 or SUS316) is the industry standard. Using mismatched metals, such as putting a zinc-plated bolt through an aluminum bracket, can lead to galvanic corrosion. This chemical reaction weakens the metal over time and can cause the mounting system to fail prematurely.

Read Also: HMS Photovoltaik: Achieve Amazing Energy Freedom

Weight and Load Considerations for 365W Panels

A 365W solar panel generally weighs between 18kg and 22kg (approximately 40 to 48 lbs). While this may not seem heavy individually, a 20-panel array adds nearly 400kg of static weight to a roof.

Furthermore, the mounting system must account for:

-

Dead Load: The weight of the panels and the racking itself.

-

Snow Load: In colder regions, the weight of accumulated snow can triple the pressure on the brackets.

-

Wind Load: The upward or downward pressure exerted by wind. Brackets must be rated for the specific wind zone of the installation site.

Comparison of Mounting Methods

Technical Installation Standards

When selecting solar brackets for 365W solar panels, checking for certifications is a vital step in quality assurance. In the United States, look for UL 2703 certification, which covers the safety of mounting systems, clamping devices, and ground lugs. In other regions, TÜV or CE certifications serve as benchmarks for structural safety and material durability.

Proper spacing is also a technical requirement. Brackets should be placed according to the manufacturer’s “clamping zones.” If the brackets are placed too close to the corners or too far toward the center of the 365W panel, the glass may flex excessively under wind pressure, leading to micro-cracks in the solar cells.

Thermal Expansion and System Longevity

Metal expands and contracts with temperature changes. Over a 20-foot run of aluminum rail, the metal can move significantly between a freezing night and a scorching afternoon. High-quality solar brackets and racking systems include expansion joints or “thermal breaks.”

Without these breaks, the mounting system can put “stress” on the 365W panels. This stress can eventually lead to seal failure around the edges of the panel or even glass breakage. When reviewing bracket specifications, ensure the system allows for this natural movement without compromising the grip on the panel frame.

Read Also: Solar Panel Lighthouse | Renewable Coastal Lighting

Essential Components of a Bracket System

A complete mounting solution for a 365W panel typically consists of several integrated parts:

-

Mid-Clamps: These sit between two panels, securing the frames of both simultaneously.

-

End-Clamps: These secure the outer edges of the first and last panels in a row.

-

Rail Splices: Connectors used to join two pieces of aluminum rail together for longer arrays.

-

Grounding Lugs: Critical safety components that connect the metal racking to the home’s grounding system to protect against lightning strikes and electrical faults.

Common Mistakes to Avoid

One of the most frequent errors in DIY or low-cost installations is the use of “universal” brackets that are not specifically rated for the dimensions of a 365W module. While a bracket might physically fit the frame, it may not provide the necessary surface area for the clamp to hold the panel securely during a storm.

Another mistake is ignoring the torque specifications. Over-tightening the bolts on a solar bracket can strip the threads or crush the aluminum frame of the panel. Under-tightening can lead to vibrations that loosen the hardware over time. Most professional systems require the use of a torque wrench to meet the manufacturer’s exact Newton-meter (Nm) requirements.

Impact on Efficiency and Airflow

The height provided by the solar brackets for 365W solar panels directly impacts the system’s performance. Solar panels lose efficiency as they get hotter. By using brackets that provide a gap of at least 3 to 4 inches between the roof and the panel, you create a chimney effect. Cool air is drawn in from the bottom, and hot air escapes from the top, keeping the cells at a lower operating temperature and increasing total energy harvest.

FAQ

Q1What is the best tilt angle for 365W solar panel brackets?

The ideal tilt angle generally depends on your latitude. For a fixed year-round system, setting the brackets at an angle equal to your latitude is a standard rule of thumb. However, in many residential roof-mount scenarios, the panels follow the existing pitch of the roof for aesthetic and structural reasons.

Q2Can I use the same brackets for different panel brands?

Generally, yes, as long as the 365W panels have standard frame thicknesses (usually 30mm, 35mm, or 40mm). The clamps used with the brackets must match the specific frame thickness of your panel to ensure a secure grip. Always verify the frame depth before purchasing your mounting kit.

Q3Do solar brackets require maintenance?

While they are designed to be “set and forget,” it is wise to perform a visual inspection every few years. Check for any signs of “tea staining” (early-stage corrosion), ensure that no fasteners have vibrated loose, and verify that the roof flashing remains intact and watertight.

Q4Are ballasted brackets safe for high-wind areas?

Ballasted systems rely on weight rather than roof penetrations. In extremely high-wind zones (like hurricane-prone areas), ballasted systems may require significantly more weight or a hybrid approach that includes some mechanical attachments to the building structure to prevent the array from shifting.

Q5How do I choose brackets for a coastal environment?

If you live within five miles of the ocean, salt spray becomes a major factor. You should prioritize “marine-grade” anodized aluminum and 316-grade stainless steel hardware. These materials have higher resistance to chloride-induced pitting and corrosion compared to standard 304 stainless steel.

Conclusion

Selecting the appropriate solar brackets for 365W solar panels is a foundational decision that dictates the safety and longevity of a renewable energy system. By matching the bracket type to the roof material, ensuring the hardware is rated for local wind and snow loads, and prioritizing high-grade materials like anodized aluminum and stainless steel, you protect both the building and the solar technology itself.

The right mounting system does more than just hold a panel in place; it optimizes cooling, manages thermal expansion, and provides the structural peace of mind necessary for a decades-long power solution. If you are planning an installation, the next step is to calculate your specific roof’s load-bearing capacity or consult a structural engineer to ensure your chosen brackets align with your local building codes.

Learn about The Pros and Cons of Bifacial Solar Panels for RVs

For broader information, visit Wellbeing Makeover

I’m Salman Khayam, the founder and editor of this blog, with 10 years of professional experience in Architecture, Interior Design, Home Improvement, and Real Estate. I provide expert advice and practical tips on a wide range of topics, including Solar Panel installation, Garage Solutions, Moving tips, as well as Cleaning and Pest Control, helping you create functional, stylish, and sustainable spaces that enhance your daily life.