Preventing a garage door roller from popping out involves maintaining proper track alignment, keeping hardware secure, replacing worn rollers, and ensuring balanced door movement. When rollers come out of the track, the door can jam, tilt, or become unsafe to operate. Proactive inspection and maintenance significantly reduce this risk and help prevent garage door roller popping out before serious damage occurs.

Regular inspections and small adjustments help homeowners prevent garage door roller popping out before misalignment leads to a stuck or unsafe door.

Why Garage Door Rollers Pop Out in the First Place

Garage doors operate on a simple but precise system: rollers attached to hinges glide inside vertical and horizontal tracks as the door opens and closes. If any component shifts out of alignment or wears down, the roller may slip out of the track.

Common causes include:

-

Misaligned or bent tracks

-

Loose track brackets or mounting bolts

-

Worn or cracked rollers

-

Broken cables or weak springs

-

Impact damage from vehicles

-

Sudden force from opening a partially blocked door

When the door loses alignment or balance, pressure builds on one side. That uneven force often causes a roller to pop free.

Understanding the mechanics behind the problem is the first step toward preventing it.

Signs Your Garage Door Rollers Are at Risk

Garage door problems rarely appear overnight. There are usually warning signs before a roller jumps the track.

Look for:

-

Jerky or uneven door movement

-

Grinding, scraping, or loud rattling noises

-

Gaps between the roller and track

-

A door that looks crooked while opening

If any of these symptoms appear, inspect the door before continued use. Operating a stressed system can worsen alignment and increase the chance of rollers slipping out. A properly functioning garage door opener can help ensure smooth operation and reduce stress on the door system.

Key Components That Affect Roller Stability

To effectively prevent garage door roller popping out, it helps to understand how each part of the system works together.

1. Rollers

Rollers may be nylon, steel, or plastic. Over time they can:

-

Wear down

-

Crack

-

Lose smooth rotation

-

Develop flat spots

Damaged rollers are more likely to slip out under pressure, especially if the door is heavy or frequently used.

2. Tracks

Tracks must remain:

-

Straight

-

Properly spaced

-

Securely fastened

Even a small bend or separation between brackets can push rollers outward.

3. Hinges and Brackets

Hinges connect door panels and hold rollers in position. If hinges loosen, bend, or shift, roller alignment changes and stability decreases.

4. Torsion or Extension Springs

Springs counterbalance the door’s weight. If they weaken or break, the door becomes uneven, placing excessive strain on certain rollers.

5. Lift Cables

Lift cables distribute tension evenly. Frayed or loose cables can cause one side of the door to rise faster than the other, increasing derailment risk.

Each component contributes to stable door movement. A failure in one area often affects the others.

Practical Steps to Prevent Garage Door Roller Popping Out

The following maintenance habits are proven ways to prevent garage door roller popping out and extend the life of the entire door system.

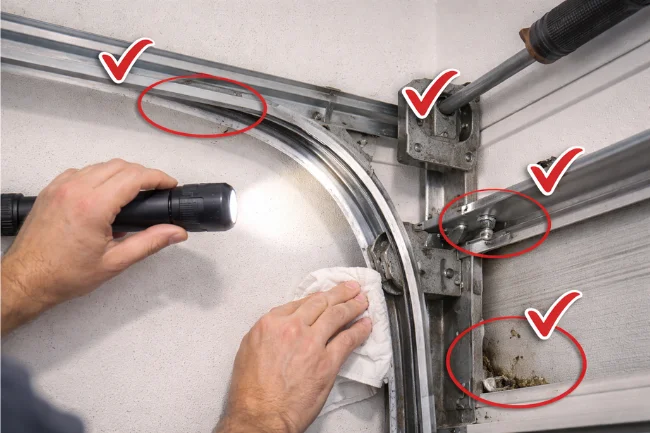

Inspect the Tracks Regularly

Examine both vertical and horizontal tracks for:

-

Visible bends

-

Gaps at joints

-

Loose mounting brackets

-

Debris buildup

Tracks should remain parallel and firmly secured to the wall. Minor debris can be cleaned gently with a dry cloth. Avoid aggressive hammering on bent tracks unless properly trained, as improper adjustments may worsen alignment.

Tighten All Hardware

Garage doors move several times a day, and vibration gradually loosens fasteners.

Check and tighten:

-

Track brackets

-

Hinges

-

Roller stems

-

Mounting bolts

Loose hardware is one of the most common and preventable causes of roller displacement.

Lubricate Moving Parts Properly

Dry or stiff rollers can stick inside the track and jump out under pressure.

Use a garage-door-specific lubricant on:

-

Roller bearings

-

Hinges

-

Springs (light application only)

Avoid applying heavy grease inside the tracks. Tracks function best when clean, as excess residue attracts dust and debris.

Replace Worn or Damaged Rollers

Roller lifespan depends on material:

-

Plastic: 5–7 years

-

Nylon or steel: 10–15 years

If rollers wobble, crack, or produce grinding sounds, replacing them is safer than waiting for failure. Upgrading to sealed nylon rollers often improves smoothness and reduces long-term strain on the track.

Check Door Balance

An unbalanced garage door strains rollers and openers.

To test:

-

Disconnect the automatic opener.

-

Lift the door manually halfway.

-

Release it carefully.

A balanced door should remain in place. If it rises or falls, spring adjustment may be necessary. Because springs are under high tension, trained technicians should handle adjustments.

Avoid Impact Damage

Vehicle contact is a frequent cause of track misalignment.

Reduce risk by:

-

Installing parking stops

-

Improving garage lighting

-

Keeping the area clear of obstacles

Even minor impact can bend tracks enough to destabilize rollers.

Preventative Maintenance Checklist

Below is a practical reference guide for routine care.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Visual track inspection | Monthly | Detect bends or gaps early |

| Tighten hardware | Every 3–6 months | Prevent vibration loosening |

| Lubricate rollers & hinges | Every 6 months | Reduce friction |

| Check door balance | Annually | Ensure even tension |

| Replace worn rollers | As needed (5–15 yrs) | Maintain smooth tracking |

| Professional inspection | Every 1–2 years | Identify hidden wear |

Consistent maintenance dramatically lowers the likelihood of unexpected roller displacement.

What to Do If a Roller Has Already Popped Out

If a roller comes off track:

-

Stop operating the door immediately.

-

Disconnect the opener.

-

Avoid forcing the door closed.

In minor cases involving one roller and no visible structural damage, careful realignment may be possible. However, if multiple rollers are off track or the door is tilted, professional service is recommended.

Forcing operation can bend tracks further and strain cables and springs.

When to Call a Professional

Some problems go beyond basic maintenance.

Professional assistance is advisable when:

-

Tracks are severely bent

-

Springs appear broken

-

Cables are frayed or detached

-

The door hangs unevenly

-

Rollers repeatedly pop out

Technicians use specialized tools to reset rollers, align tracks, and rebalance spring tension safely.

For property owners managing rental or commercial spaces, routine professional inspections help maintain operational reliability and safety standards.

Long-Term Prevention Strategies

Routine care is essential, but structural improvements can provide stronger long-term stability.

Upgrade to High-Quality Components

Lower-grade rollers and thin tracks are more prone to deformation. Investing in durable materials:

-

Improves lifespan

-

Reduces vibration

-

Enhances stability

Quality components reduce stress throughout the system and help prevent garage door roller popping out permanently.

Ensure Proper Installation

Improper installation is a leading cause of recurring alignment problems. Correct spacing and leveling during installation establish long-term reliability.

Address Minor Issues Early

Small alignment concerns can escalate quickly. If you notice rubbing, uneven lifting, or mild shaking, early correction reduces strain and prevents larger mechanical failures.

Environmental Factors That Contribute to Roller Issues

External conditions influence garage door performance.

-

Temperature swings cause metal expansion and contraction.

-

High humidity increases corrosion risk.

-

Dust accumulation clogs bearings.

Regular cleaning and lubrication reduce environmental wear and support smooth operation year-round.

Common Myths About Garage Door Rollers

Misunderstandings often lead to improper fixes.

Myth: The track should be heavily greased.

Tracks function best when clean. Heavy grease attracts debris and increases friction.

Myth: If one roller pops out, it’s minor.

Even a single displaced roller indicates imbalance or misalignment.

Myth: Hammering bent tracks solves the issue.

Improper straightening can weaken structural integrity and worsen alignment.

Accurate knowledge supports safer maintenance decisions.

The Safety Aspect of Roller Maintenance

Garage doors are among the largest moving components in a home. A door that jumps track can:

-

Damage vehicles or stored items

-

Jam unexpectedly

-

Create pinch hazards

Preventative care protects both mechanical components and household safety.

How Routine Service Protects Your Investment

A garage door is a significant structural feature that supports daily convenience. Proactive maintenance:

-

Extends system lifespan

-

Reduces emergency repair costs

-

Improves reliability

-

Maintains smooth operation

Scheduling periodic service ensures small concerns are corrected before they develop into disruptive failures.

Frequently Asked Questions

1- Why does my garage door roller keep popping out?

Repeated displacement typically indicates track misalignment, worn rollers, or imbalance caused by spring tension problems. Resetting the roller without correcting the underlying issue often results in recurrence.

2- Can I fix a popped-out garage door roller myself?

Minor cases involving a single roller and no visible structural damage may be manageable. However, if the door appears crooked or multiple rollers are affected, professional service is safer due to the tension within spring systems.

3- How often should garage door rollers be replaced?

Roller lifespan depends on the material and usage. Plastic rollers may last 5–7 years, while high-quality nylon or steel rollers often last 10–15 years. Regular inspections help determine appropriate replacement timing.

4- Does lubrication prevent rollers from coming off track?

Lubrication reduces friction and wear but does not fix alignment or structural problems. Combining lubrication with track inspection and hardware tightening provides more reliable prevention.

5- What happens if I keep using a door with a popped roller?

Continued use can bend tracks further, strain springs, and damage door panels. Immediate inspection reduces the risk of costly structural repairs.

Maintaining Smooth, Stable Operation

Prevent garage door roller popping out by keeping tracks aligned, tightening hardware, replacing worn rollers, and maintaining balanced spring tension. Most problems develop gradually and can be corrected early through routine inspection.

When recurring issues arise or structural damage is suspected, a professional evaluation restores proper alignment and ensures safe operation. A well-maintained garage door protects vehicles, belongings, and daily convenience while supporting long-term reliability.

For broader information, visit Wellbeing Makeover

I’m Salman Khayam, the founder and editor of this blog, with 10 years of professional experience in Architecture, Interior Design, Home Improvement, and Real Estate. I provide expert advice and practical tips on a wide range of topics, including Solar Panel installation, Garage Solutions, Moving tips, as well as Cleaning and Pest Control, helping you create functional, stylish, and sustainable spaces that enhance your daily life.